Common Causes of Hydraulic Pump Failures

Hydraulic pumps are the heart of many industrial systems, powering everything from construction machinery to manufacturing equipment. When they work, they're great, but when they fail, this can cause big problems. Understanding why hydraulic pumps fail is key to preventing downtime and costly repairs. Dive into the common causes of hydraulic pump failures and explore effective solutions to keep your systems running smoothly.

Contamination: The Silent Pump Killer

Tiny particles that shouldn't be there can get inside and cause a lot of damage. These particles can come from various sources, like dirty oil or a contaminated environment. They can wear down the pump's parts, leading to leaks or total failure.

The solution? Keep things clean. Regularly changing the hydraulic oil and filters can go a long way. Also, make sure your environment is as clean as possible to prevent external contamination.

Overheating: When Things Get Too Hot

Overheating usually happens when the oil temperature gets too high, which can damage the pump. Overheating can be caused by a few things, like using the wrong type of oil, a clogged filter, or a system running too hard for too long.

To fix this, check the oil type and make sure it's right for your pump. Regularly check and clean the filters, and give your system a break now and then to cool down.

Aeration and Cavitation: Bubbles and Voids

Aeration happens when air gets into the hydraulic fluid, while cavitation occurs when there are voids or cavities in the fluid. Both can cause serious damage to the pump. Aeration can make the oil foamy, which reduces its effectiveness. Cavitation can happen when the fluid's pressure drops too low and it starts to vaporize.

To prevent these issues, check for leaks and fix them fast. Also, keep an eye on the fluid levels, and make sure the pump is properly primed to avoid introducing air into the system.

Improper Sizing or Installation: A Bad Fit

Sometimes, the problem starts right at the beginning. If a pump is the wrong size for the system or if it's not installed correctly, it won't work right. A pump that's too small won't be able to handle the load, while one that's too big can cause excess wear and tear.

Make sure you get the right size pump for your needs. If you're not sure, consult with a professional. Also, follow the manufacturer's guidelines for installation to ensure everything is set up correctly.

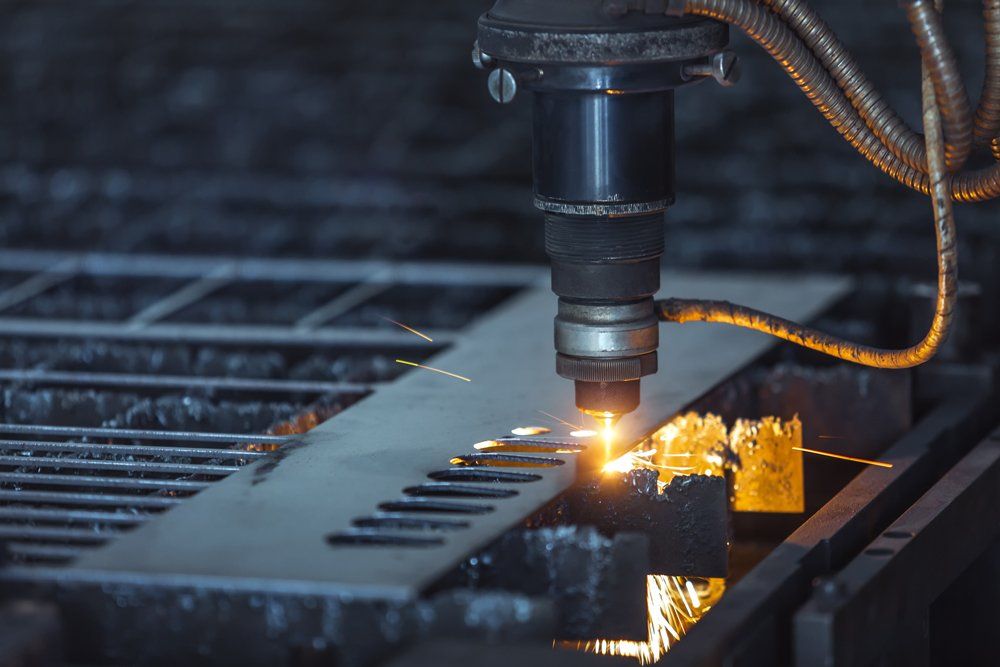

Wear and Tear: The Inevitable Aging

Like anything else, hydraulic pumps can wear out over time. This is a normal part of their lifespan but can lead to failures if not managed. Regular wear can cause parts to degrade, leading to decreased performance and eventually failure.

The best solution here is regular maintenance. Regular check-ups can catch problems early, and replacing worn parts can keep your pump running smoothly.

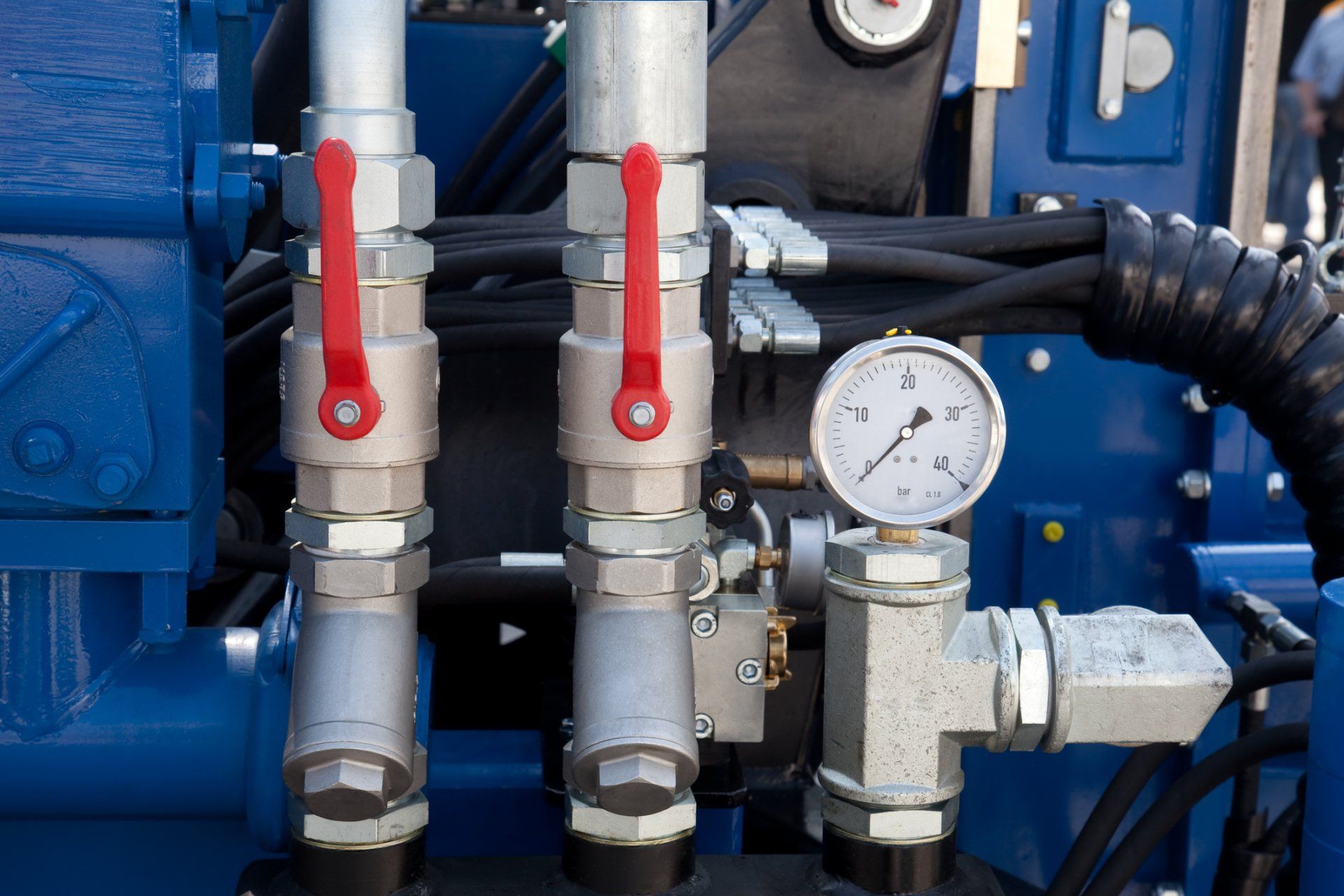

Mismatched Components: The Pitfalls of Incompatibility

Hydraulic systems are complex, and each part needs to work in harmony with the others. If components like valves, hoses, or fittings are not compatible with the pump or with each other, this can lead to increased stress on the pump. This stress can cause premature wear and tear or even complete failure.

The key to avoiding this is ensuring that all components of your hydraulic system are matched and compatible. This might mean checking the specifications of each part carefully and consulting with experts when replacing or upgrading any component. Proper compatibility not only extends the life of the pump but also ensures the efficiency and reliability of the entire hydraulic system.

If you're facing hydraulic pump troubles or want to prevent them before they start, reach out to

Quad Fluid Dynamics, Inc., for assistance.