5 Specialty Hydraulic Shop Tools

A hydraulic machine shop is a specialty workshop that focuses on creating high-precision metal components for a wide range of industries. The main attraction, naturally, is the hydraulic press, an incredibly powerful and complex tool that has dozens of unique applications. Having access to a hydraulic press allows metallurgists to perform unique and useful tasks that would otherwise be impossible.

However, a quality hydraulic shop has many other tools that can expand the scope of what the metallurgists can accomplish. In addition to more common tools, such as arc welders, band saws, and drills, many shops enjoy access to specialty machinery. Read on to learn about five of the unique and useful tools that well-equipped hydraulic shops should choose to invest in.

1. CAD Workstations

A computer-assisted design (CAD) workstation is a series of computers that are connected to high-precision machining tools. Sheet metal is placed on the workstation, and instead of using hand tools to directly machine the metal, you use a computer program to dictate the exact cuts and grinds to be made, and an automated system does the rest.

CAD workstations allow metallurgists to achieve extreme precision quickly and easily. If you need a large volume of precise metal parts, a worker with a CAD workstation can get them done in a fraction of the time it would take to process the parts traditionally.

2. Lathes

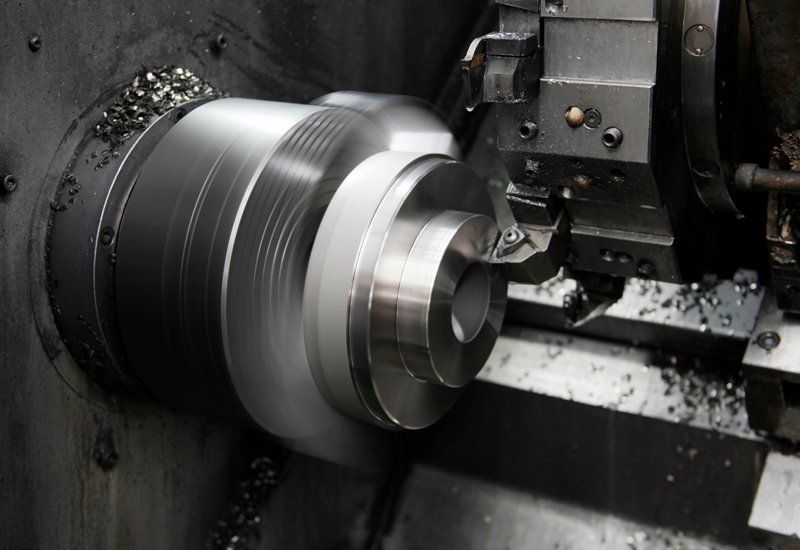

You may already be familiar with wood lathes, the tools that spin wood around rapidly and allow you to make things like cups, bowls, and pens very quickly. Did you know that metal lathes exist as well? A tool like a computerized numerical control (CNC) lathe can allow you to create circular parts of the exact diameter you need, and vertical turning lathes provide immense power to create large parts.

3. Grinders

A grinder is tool that spins a disc at rapid speeds. When you press the disc against the metal, you shave off tiny layers of metal, allowing you to get a smooth finish and achieve a perfectly level edge. Angle grinders are great for small jobs, and surface grinders are more heavy-duty and allow you to guarantee a flat finish.

Inside diameter (ID) grinders allow you to remove metal from the inside of circular pieces, such as pipes. Conversely, outside diameter (OD) grinders shave off the outer layer. In short, every grinder is designed to remove some mass from a piece of metal, bit by bit, until it's exactly how you want it.

4. Borers

The borer family of tools is essentially comprised of large, extra-powerful drills. They're designed to create precise holes that extend deep into metal parts. A jig borer creates small lead holes that will then become the center of larger holes. These larger holes are often made by a horizontal boring mill, a large machine that can drill clear through any metal surface.

Due to the sheer power needed to create large holes through metal, boring mills are large and expensive. Nevertheless, their utility cannot be ignored, and most serious metal shops have access to one.

5. Lapping Machines

Towards the end of the project, metallurgists will employ a lapping machine to create truly flattened and polished surfaces. A lapping machine employs a liquid slurry made from small abrasive bits combined with water or oil. It applies the slurry to the surface, and then uses a relatively soft grinding wheel to scour the surface of the metal into an incredibly smooth, flat surface.

Quad Fluid Dynamics, Inc.

, offers a full suite of metalworking services. No matter what kind of part you need made, we'll manufacture it with unmatched precision. Get in touch today to learn how we can help you get the parts you need.